Although our core team has been mostly working this summer, many collaborators, partners, and their subcontractors have had holidays. In our case this means that for two months everything has been going on slower as usual; in Finland, July is a holiday month and in central Europe it is August.

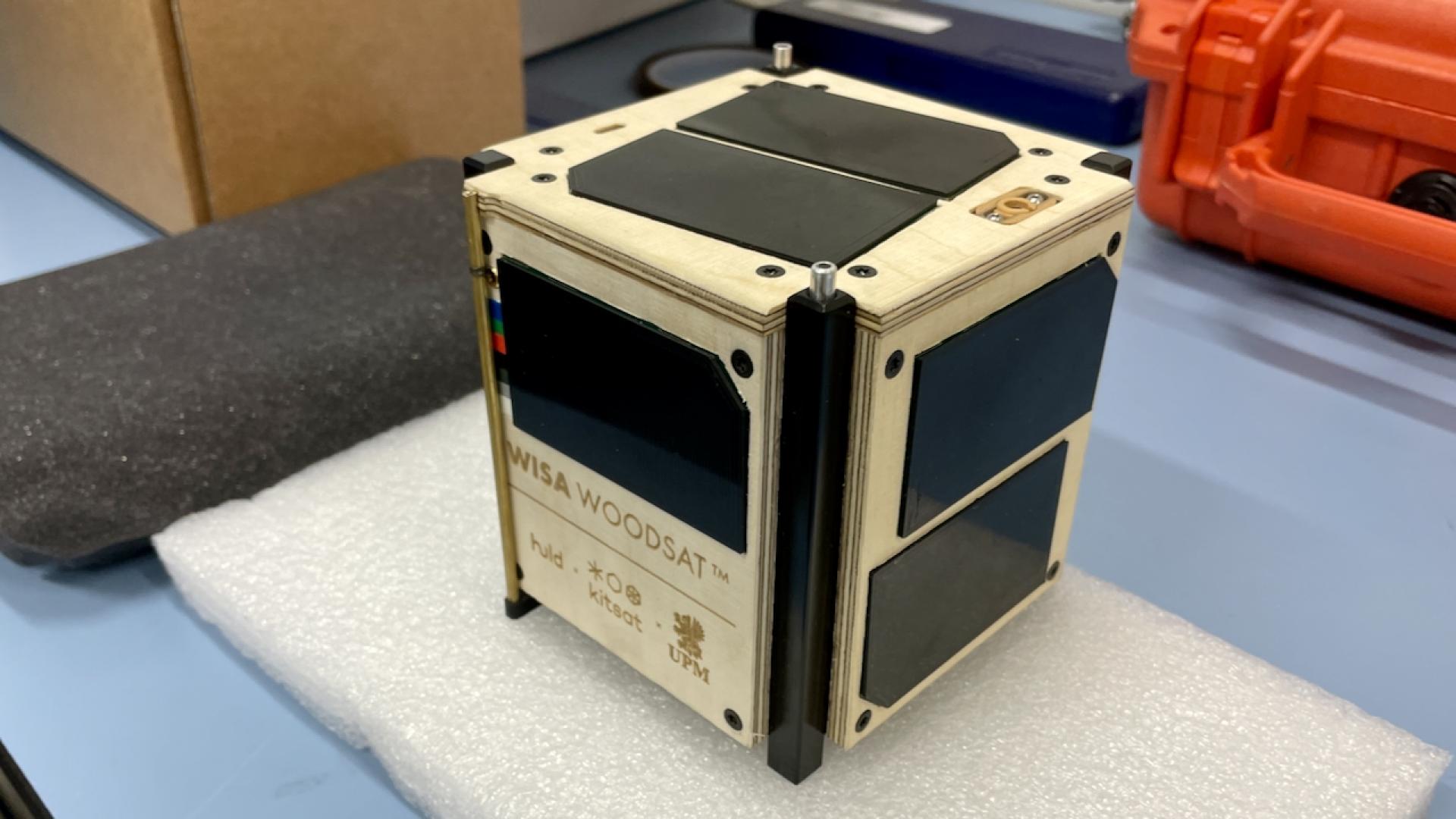

Since the vibration tests at ESTEC in July, we have done some modifications to the satellite, based on the results. Despite two loose screws the mechanical structure of the WISA Woodsat met the requirements and behaved nicely. As the tests are made not only for verifying the design, but also for making it better, so we decided to do two minor, but still important changes.

Our launch time has also been pushed ahead from September 2021 (that was originally planned) towards the end of the year, so we have time for polishing our design.

The first modification will be clearly visible from the outside because the sharp edges of the plywood panels will be slightly rounded. We have noticed during the process some splintering of the dried plywood, and even if this is not mission-critical and is less significant when the plywood panels are coated, we’ll round the edges in the satellite.

The rounded shape of the top panel was originally only because of the artistic appearance, a nod towards the minimalist Nordic furniture design. This rounded edge turned out to be also good from the splintering point of view.

The rounding of the side panels will be smaller, but still, that will slightly change the looks of the satellite.

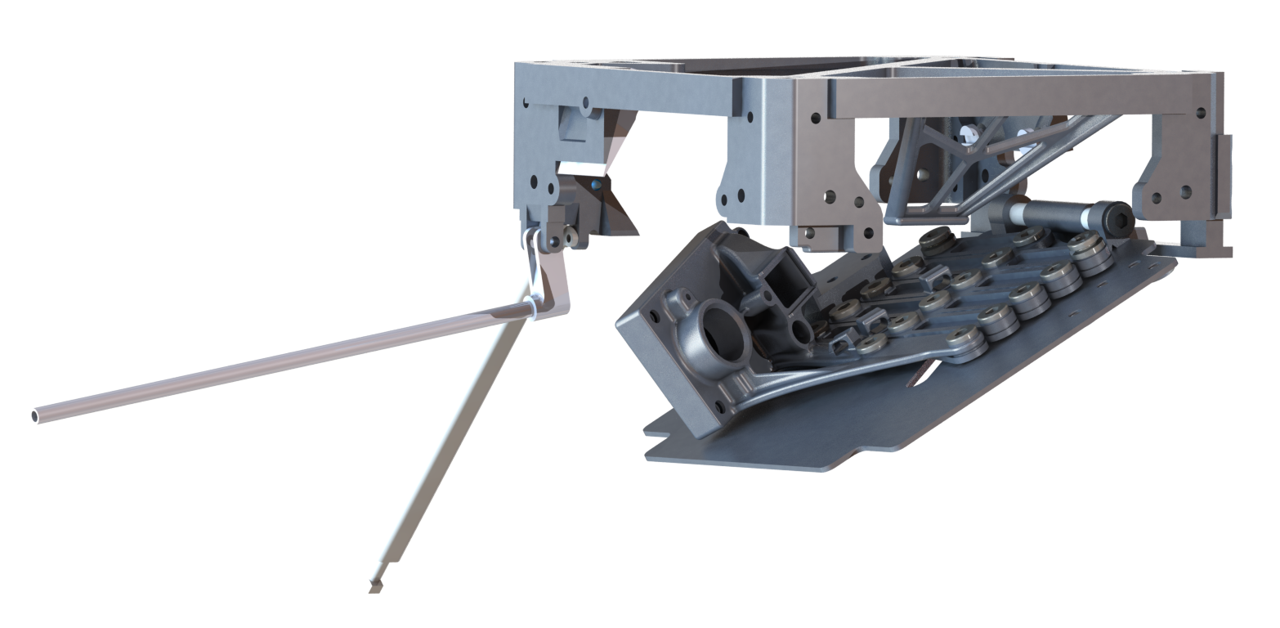

Another change is not visible from the outside. The structure supporting the camera boom was made from two parts previously, but as Kevin and Jaakko at Huld found out how it could be made from one part, it will of course be done so. This saves again weight and makes the structure as simple as possible, using as little as possible metal.

In fact there will be a small change in the selfie stick as well: the screws will be now black. With the original shiny ones there was a possibility of having reflections of the sunlight in the photos taken by the camera, but now there won’t be. Small, but important thing.

The manufacturing of these modified parts is going on right now and according to our updated schedule the assembly of the satellite and the EQM (both are identical) will take place from the end of September on and we’ll be ready for the final tests in November.

The ESA payload and experiment from Captain Corrosion in Estonia will arrive also in September.

The assembly of the satellite will be done at the cleanroom of Aalto University, our Alma Mater. It has been a home of many Finnish satellites, like the Suomi 100 satellite – a satellite that may be considered as a grandfather of WISA Woodsat.

Interesting times ahead!